What exactly does pse and PSC conformity tests do? Easy 5 Flows

この記事は約 29 分で読めます。 1,574 Views

Hello. It is a hori of the manager.

For both PSE's specified electrical appliances and PSC products, conformity inspections by registered inspection bodies designated by the Ministry of Economy, Trade and Industry, so-called factory inspections are required.

This is the process by which the certification body confirms the equipment and production system of the production plant after the product sample inspection is completed.

As the background to the implementation of factory inspections, pse specified electrical appliances and PSC products, etc. have a complex product structure, and if a product accident occurs by any chance without being produced under the established safety standards, it may seriously interfere with the lives of the people.

In other words, if it is only a product, it is also possible to make it at a factory somewhere and submit it.

Therefore, we check the address of the factory in advance with official documents, etc., and the inspectors actually go out to check the site, and then check the production system, etc., and make sure that the product is made with a proper system at the factory.

That being said, those who are considering inspections do not know what will be done specifically in factory inspections. The reason is that there is no information. There are about three main reasons for this.

In the first place, when considering the population ratio, one point is that there are overwhelmingly few businesses that undergo PSE and PSC compliance tests,

The other is that I don't bother to write on my blog with the feeling that manufacturers and factory workers are reluctant to receive it at work. There may also be a relationship of confidentiality,

And the biggest problem is that basically, it is determined by law that certification bodies cannot disclose the contents of conformity inspections and cannot disclose them to clients in advance.

It seems that fairness is aimed at all operators, including those who may become clients in the future, but it is an honest impression that I myself who is doing this job does not come a little.

However, in any case, with such a rule at present, business operators who undergo conformity tests for the first time will not be able to pass 100% unless consulting is included. It is natural because measures cannot be taken if you do not know the test items.

This time, I experienced PSC conformity inspection as a requester and supported the customer's PSE / PSC conformity inspection, so it is easy from the standing position, but please refer to what is actually being done on site.

Contents

- 1 In the first place, confirm the positioning of conformity inspections in a series of inspections

- 2 What is actually done with conformity tests?

- 3 Points to stumble upon during inspection

- 4 Preparation and caution in advance of conformity inspection

- 5 An example of support that we can do with many conformity inspections

In the first place, confirm the positioning of conformity inspections in a series of inspections

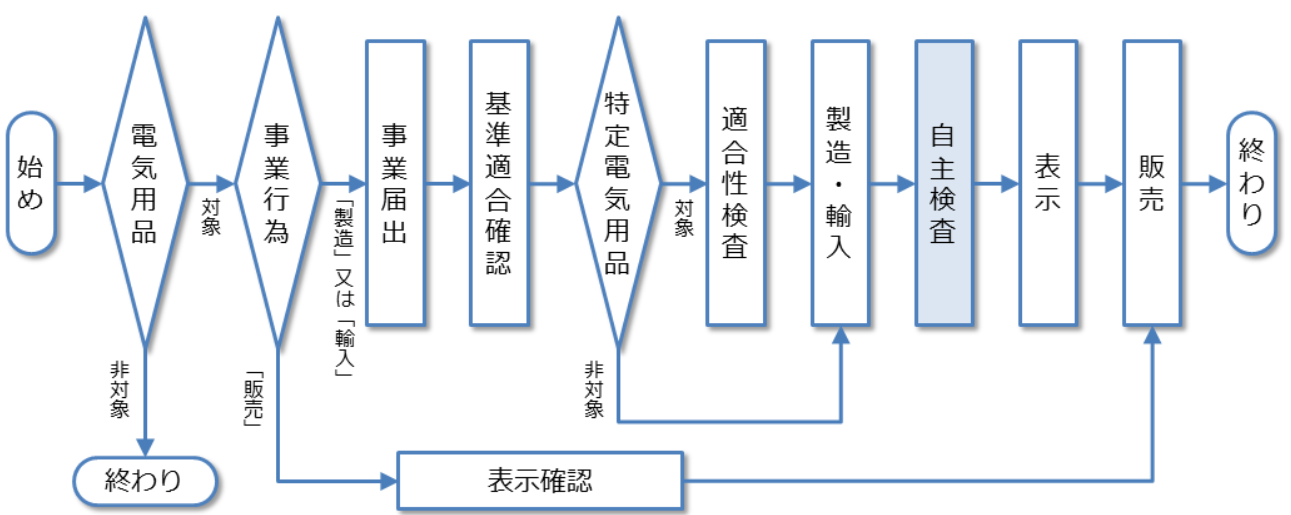

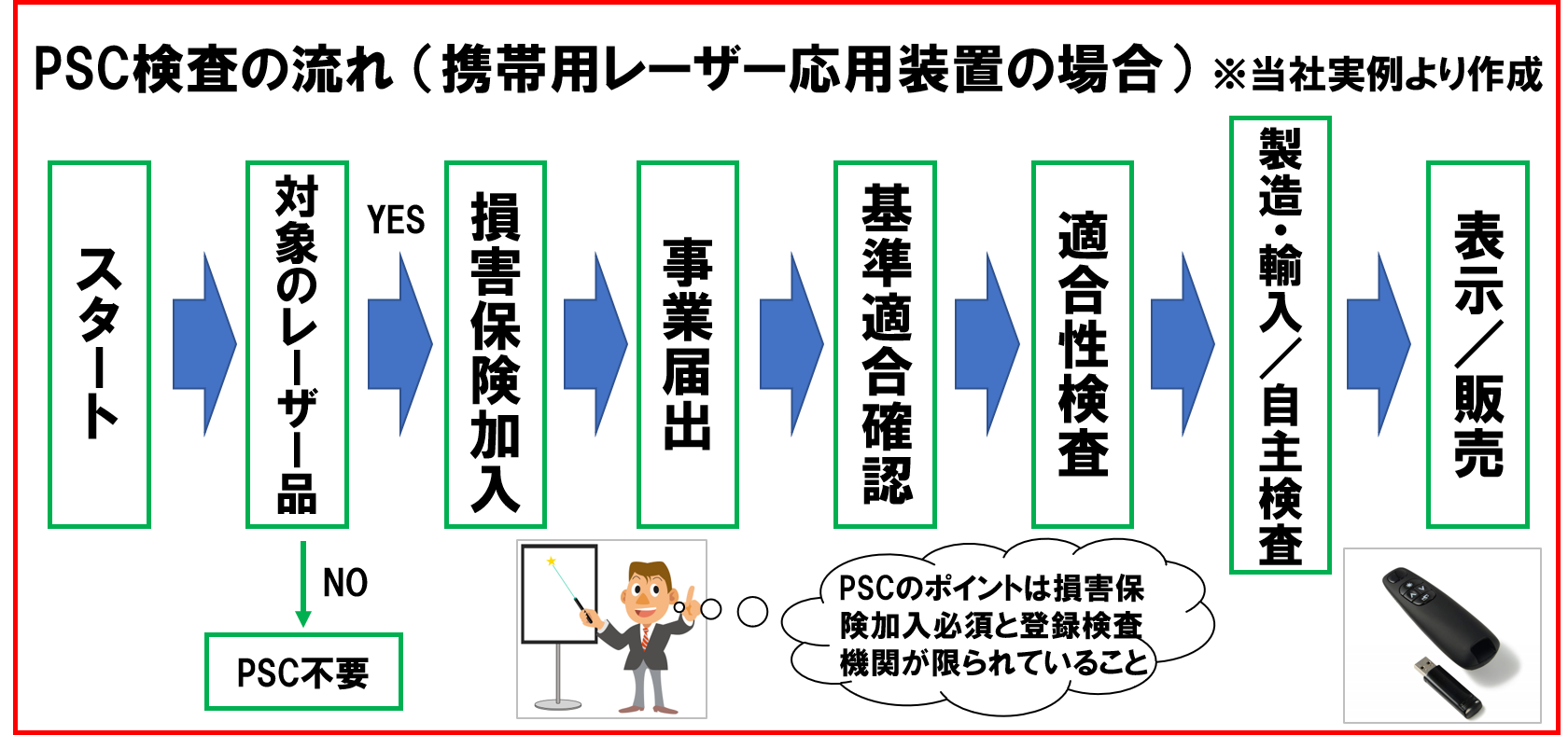

Let's take another look at the pse and PSC inspection flows that have appeared several times so far.

There is an item called conformity inspection (factory inspection) in each flow, and if it passes, a certificate will be issued, and the business operator will finally be able to manufacture and sell. By the way, the standard conformity confirmation before one of the conformity inspections is a sample inspection.

There is an item called conformity inspection (factory inspection) in each flow, and if it passes, a certificate will be issued, and the business operator will finally be able to manufacture and sell. By the way, the standard conformity confirmation before one of the conformity inspections is a sample inspection.

The reason for the sample inspection first is that the sample does not necessarily pass the test at once, there are many things to remake several times, and it is basic to perform a factory inspection in a state where the completed form can be made.

What is actually done with conformity tests?

I'm worried about what kind of amazing things are done: conformity inspection, that is, "factory inspection". Strange story, do you inspect all the factories?

There is no such information at all.

For example, if you ask overseas factories to cooperate in factory inspections without knowing the actual situation of factory inspections, you will definitely be refused.

As a matter of fact, what kind of inspections do you want?

If it does not understand it, the factory cannot cooperate either.

Factory inspection confirms the production line and inspection equipment of the product to the last

First of all, it is a major premise, but we do not confirm all of the factories. Even factories do not make only one product, but because they make a wide variety of products from multiple companies, of course there is a duty of confidentiality.

The certification body is not authorized to view any information other than the product.

Check production lines

The certification body confirms the general construction and configuration of the factory, for example, the factory is also operating on multiple lines, so we will check which line the certification product will be produced on. In short, it is an image of a survey of production conditions.

Confirmation of inspection equipment

For example, for PSE electrical appliances, insulation testing is essential, but the factory has inspection equipment that complies with PSE standards, and checks whether the machine is faulty and whether the factory person is able to use it.

In addition, in terms of PSC laser pointers, a machine that measures the wavelength and waveform of a laser beam is required, and as in pse, correct handling is required.

Conversely, this is the only thing to check.

The rest is a chat-based question about the factory itself. As a factory, you may refuse to respond if it is not directly related to the inspection. However, I don't think the inspectors will hear from the beginning that they will be refused an answer.

The inspection time ends in about half a day, and the inspector takes home the inspection contents and, if there is no problem, a certificate is issued in conjunction with the sample inspection already carried out.

Meeting scenery at the time of factory inspection (1)

Points to stumble upon during inspection

I wrote that the inspection time will be over in about half a day, but if it does not end with that much, both the inspector and the factory have the next schedule, so it will be the business's job to give instructions to the factory so that the inspection proceeds quickly.

It is good if the factory is accustomed to the conformity inspection of PSE and PSC, but such a factory will be rare both in Japan and overseas, and I think that most of them are the first inspections, so it is necessary for the operator or its representative to instruct the factory in detail.

In that, the stumbling points during inspection are listed.

Unable to communicate with inspectors due to linguistic problems

This is also described in the proviso of the certification body, so it will be okay indeed, but for example, when a Japanese inspector visits the factory, if there is no person who can speak Japanese at the factory, there is no way to proceed with the inspection. Basically, inspectors can't speak foreign languages.

On the other hand, if you use an overseas inspection organization such as CQC for a Japanese factory inspection, Chinese people will do factory inspections, so you need human resources (interpreters) who can speak Chinese at the factory.

In addition, it is not mandatory for the requester (the business operator himself) to be present at the site of the inspection of the factory. If there is a person who is actually operating and working at the factory, and you can communicate verbally with the inspectors, there is no problem.

The material requested to be disclosed does not come out immediately.

When checking the operating status of the inspection equipment, it is necessary to also check whether the machine is really a facility that complies with PSE and PSC standards, so you will be asked to disclose the certificate. At that time, if the documents do not come out immediately, it will be a loss of time.

It may end up being too motamota to finish all the tests. At that time, it would be good if you should send data later, but if it becomes a later start again because the inspection has not expired, it is really fatal.

The documents to be asked are roughly decided, so let's make sure that such things can be put out immediately.

I can't answer questions about equipment and machinery.

I think that it has hardly done so if it is a person in the factory, but for example, if both PSE and PSC have introduced equipment only to make the product, the person in the factory may not fully understand the usability of it, so let's be thorough in that respect.

Meeting at the time of factory inspection (2)

Factory (1)

Preparation and caution in advance of conformity inspection

I wrote the notes during the inspection first, but I will return the story a little while ago and write that measures are necessary before the conformity inspection implementation, that is, during certification application and sample inspection.

Know the correct address for your factory

In particular, it is better to recognize that the address listed in Alibaba etc. is definitely wrong. I don't know if it's intentional or happen to be there, but for some reason the China factory doesn't try to announce the correct address.

In order to start certification, it is necessary to notify the Ministry of Economy, Trade and Industry and the certification body of the Factory, but be sure to visit the factory site and grasp the exact address before conformity inspection. There is a certificate at the entrance of the factory, so let's suppress it.

Then, once you have the correct address, make sure you submit a change notice. If you do not do it and face the conformity inspection as it is, there is a high possibility that you will fail in one shot because of the mistake of the address description contents.

In the case of a Japanese factory, such a thing might be few, but it may still be good to check it with the register etc. In the unlikely event that it fails and suffers damage, it is the business operator.

Factory certificates

Create and submit the correct list of inspection equipment

I do not feel like a trap here, but I will submit a list of inspection equipment of the factory at the time of certification application. Neither YES nor NO are said for this document.

If the operator does not know anything, the test will proceed as it is even if there is a deficiency in the contents, and when the inspector goes to the factory, the equipment of the list contents will fail the test.

If you are a business operator who is enough to undergo PSE / PSC compliance inspection, I think that you have cleared that area by examining various things, but basically, there is no attention from the certification body,

Be careful.

Resubmissions of the list are allowed prior to conformity inspection, so check carefully and respond to resubmissions as soon as any deficiencies are found.

Have the correct inspection equipment in place for the list

Even if it is said inspection equipment, it is not necessary to do anything that can cost as much as 1 million yen, and some things such as tens of thousands of yen sold on Amazon are enough.

The important thing is to check the necessary inspection equipment and have factory staff remember the operation.

If the factory has the equipment for a long time, there is no problem, but if it is introduced for the product, it will be the first time to use it, and basically it will be used only with that product, so there is a possibility that the usage will remain unfamiliar.

Let's urge the respect to be prepared beforehand because it is likely to become troublesome if the appearance is seen by the inspector at the inspection, and it is variously thrust.

Factory (2)

An example of support that we can do with many conformity inspections

Briefly, we looked back on the outline of the conformity inspection and the precautions.

As I told you, if you are only told to do "factory inspection (conformity inspection)", you tend to fall into the sense that you will be involved in the outrageous work of what you will do as a whole, but if you organize what you actually do, you can understand that there is not much difficult things waiting for you.

Unfortunately, however, just because the image of what you do boils, there is no such thing as whether you can perform conformity inspections on your own.

If you look at this content, you may have already noticed, but in the end, in order to complete the business, it is essential to have a consultant who will bridge the inspection organization and the production plant.

In addition to sample inspection, we need to identify the necessary equipment, create a list, and if there are any deficiencies in the equipment, we must prepare the necessary items, and we must remember how to use them.

This is not a serious thing because it is an overseas factory, and even in factories in Japan, the factory itself is not necessarily familiar with PSE and PSC, so the existence of a business consultant is indispensable if it proceeds efficiently.

Finally, we will introduce our business, but we would appreciate it if you could see what you can do specifically. On top of that, I would like you to compare it with other companies.

In addition, we accept requests in various patterns of only confirmation of standard compliance (sample inspection), only conformity inspection (factory inspection), and both sets. Basically, both sets will work the most smoothly.

Creation of equipment product list, pointing out missing equipment, etc.

We have absolute confidence in the know-how on the equipment list that we have talked about several times.

In particular, there were some people who managed to reach the standard conformity confirmation on their own, but we asked us that we could not do compatibility inspections by ourselves alone.

Standard conformity confirmation and conformity inspection are completely different things, especially about the equipment product list because it is information that never comes out even if you search on the Internet, so I think that you can think that there is no choice but to outsource here.

Factory advance guidance / Factory inspection meeting

In particular, you can't tell what kind of facilities the Chinese factory has unless you actually look at it. Even if the documents are supposed to be well equipped, it can be assumed that there is actually nothing if you open the lid.

In addition, if you do not tell the factory staff directly in advance what will actually be done in the conformity inspection and understand, you may not be able to move anything at the site on the day.

You should also check the difference between the factory's nominal and actual addresses, as mentioned earlier.

In the sense of these confirmations, it is considered essential to provide advance guidance to the Chinese factory.

On the other hand, regarding factory inspection meetings, if factory staff and inspection agency staff from the same country are well prepared in advance, there is a high possibility that they will be able to do something without being present, but when it comes to foreign countries, communication will not be established in the first place due to language problems.

We have Japanese-language-friendly Chinese engineers who are familiar with Japanese certification, so we can solve all such problems.

Introduction of the best certification body, technical guidance to the factory

Today, the coronavirus has made it virtually impossible for inspectors to move between countries.

Then, it can be imagined that the inspection of PSE specified electrical appliances and PSC products including conformity inspection will be done at the inspection organization in the country where the production plant is located for a while.

For example, when conducting conformity inspections at a factory in China, it is necessary to use CQC, etc., but if we are there, there is no problem in terms of language. Rather, since we have been working with CQC many times, our strength is that it can be done more smoothly than usual.

On the other hand, we can fully respond to conformity inspections in Japan.

In addition, PSC is only recognized by inspection organizations in Japan such as JQA and UL Japan, and it tends to be thought that inspections at overseas factories will not be realized unless the ban on travel is lifted, but for example, if we have found a factory in Japan that can be a saucer, we can provide technical guidance and build a system that can be inspected.

I briefly wrote about what is actually done about PSE and PSC conformity test. In the future, we would appreciate it if you could refer to it when you need certification of such a product.

Commemorative photo with the president and manager of the factory