【Certification example】Pse certification of rotary-type power supply taps used in a wide range of fields such as educational facilities and various work environments

Hello. It is a hori of the manager.

This time, we will tell you our case study.

Our customers are Takachiho Trading Co., Ltd. (listed on the First Section of the Tokyo Stock Exchange) as a "technology trading company" centered on electronics, and is one of the first companies to introduce (sell) the world's leading products to the Japanese market.

The product that received the request for certification is "wheel number type power strip". We have done PSE certification (specified electrical appliances) for this type of product in the past.

In a situation where the time limit for delivery time and sales is clearly set, in order to meet the planned product release time, we were informed of our company that can be certified quickly using overseas inspection agencies, and we contacted you.

We also made use of our experience so far, but there were several difficulties along the way, and we were able to provide services using technical capabilities each time, and we managed to finish the certification by the deadline.

I think that there is a part that will be helpful even a little for those who are considering authentication from now on, and we will publish the article.

Contents

Requester

Takachiho Trading Co., Ltd.

Junichi Watanabe

Interview: INSIGHT WORKS Co., Ltd. Hori

Official website: https://www.takachiho-kk.co.jp/

(Corporate Philosophy)

"As a technology trading company, we place "creation" as the starting point of our business activities"

1. Through technology, we enhance customer satisfaction.

2. We will hone our skills and humanity and build world-class trust.

3. We will work together to open up a prosperous future and contribute to society.

Quoted from the company's website

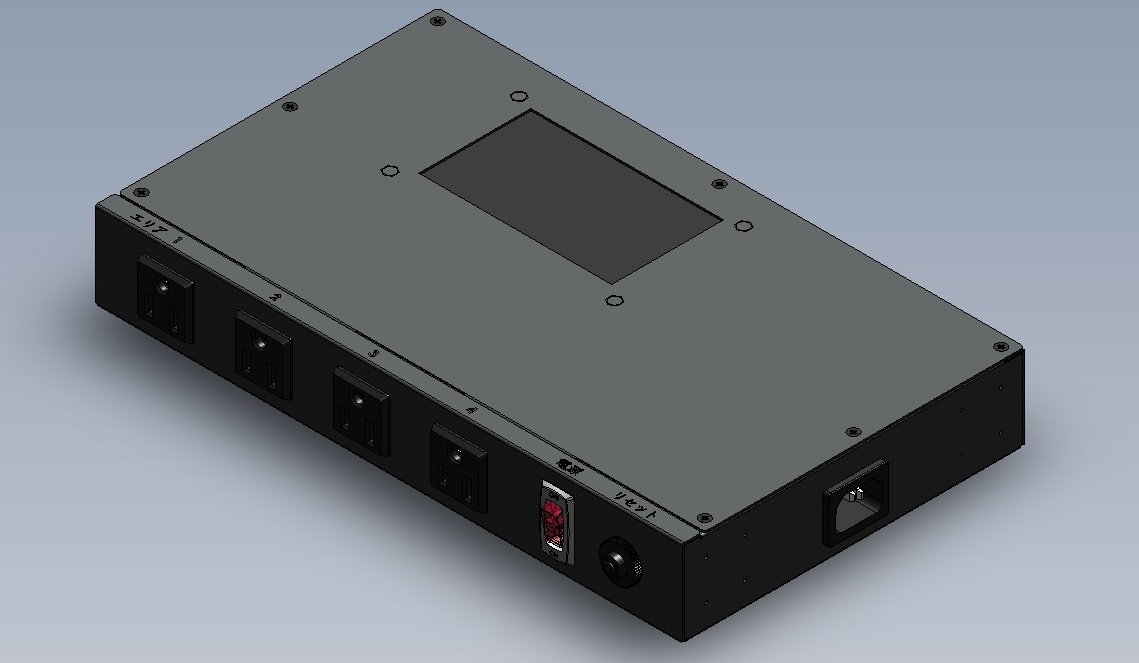

Overview of "AC Charging Wheel Number Timer Unit with Touch Screen" certified

Hori: Before we talk about certification, I would like to look back a little bit about the product overview.

Hori: The "Rotary Power Strip", which has been featured as a case study of our company before, is a product that can automatically switch multiple power supplies on / off due to time difference to control power supply and stably supply power to each device without cuts.

Mr. Watanabe (hereinafter Referred to as Watanabe): As I will explain later, I actually saw the case study article of INSIGHT WORKS and made an inquiry for certification.

Hori: The product outline is posted on the homepage of Takachiho Trading Co., Ltd., so I would like to quote that.

Ac wheel number charging unit with touch screen it is an AC wheel number charging unit with a touch screen corresponding to the specifications of the GIGA school concept such as schedule, timer, 1500W breaker.

[Product Features]●Easy-to-handle operation panel

Easy charging schedule timer setting with touch screen, no complicated operation and user-friendly design

●Equipped with a schedule timer function

Equipped with a weekday and Saturdays and Sunday batch setting modes, a total of 12 charging schedules can be set from Monday to Sunday, and timer time / charging area can be set up to 150 minutes in increments of 0 to 15 minutes

● Power strips can be connected to up to 4 ports

It also supports our 11-port power supply tap and set sales, in which case up to 44 devices are charged

※ The photograph is under development, it may be different from the actual specifications.

Citation: Takachiho Trading Co., Ltd. HP

Hori: The rotary power strip is used for initiatives to give tablets, PCs, etc. to each student in school classes in the GIGA School Concept promoted by the Ministry of Education, Culture, Sports, Science and Technology.

Watanabe: Yes. Our products are installed and used in PC charging storage, but they are designed with a touch screen function for ease of use for easy user handling. In addition to educational facilities such as schools, in addition to various work environments such as offices and production factories, in addition to wheel-numbered power strips, we also have a lineup of high-performance TYPE-C power supply units so that customers can select the optimal products in various environments.

Hori: Thank you for introducing our products. Now, I would like to look back on this certification.

How I asked INSIGHT WORKS for authentication

Watanabe: Originally, we planned to perform PSE certification using a Japanese inspection organization. In such a way, the Taiwan factory that requested production contacted us that there was a high possibility that the certification would not be in time by the deadline we wanted to have at the Inspection Agency in Japan.

Hori: You heard from a production plant about PSE. It is a very excellent factory.

Watanabe: The factory is expanding globally, and I was able to contact you because I had experience in acquiring PSE in Japan.

Watanabe: I discovered INSIGHT WORKS when I was looking for an agency that could move overseas inspection institutions because I thought that if the factory was overseas or Taiwan, it would not necessarily be necessary to use a Japanese inspection organization.

Hori: Thank you. We also post examples of using overseas inspection organizations on our website, so I think you have a look at them.

Watanabe: In that context, I saw the case of an overseas inspection engine for a rotary power strip, and I thought that this company would do something about it, so I contacted Mr. Hori.

Hori: Mr. Watanabe contacted us, and because it was an urgent task, we promptly set up an online meeting at Takachiho Trading, Taiwan Factory, and our company (+ engineer). In addition, we have advanced it because it is limited express correspondence treatment in all future.

Conduct online meetings

Hori: In addition to Mr. Watanabe, mr. Takachiho Was involved in the meeting, and we asked about the background of this certification and the time limit of certification.

Watanabe: I knew that the schedule was quite tight, but there were parts that I thought there was no point in selling until I authenticated if I didn't meet the time limit in the first place. When I told Mr. Hori and the engineers about this story, I was relieved to say that it would be in time for the schedule.

Hori: In fact, the fact that authentication must be finished by when can be broken down into several pieces. Whether it is necessary if the product test is completed for the time being, whether it is necessary to have completed certification including document confirmation, whether a certificate needs to be issued.

Hori: When I asked Mr. Watanabe about such a point, he replied that if the exam had been completed by when, it would be okay to proceed while confirming afterwards. Since the goal setting has become clear, we have decided to proceed with the certification arrangement for that.

Get a product explanation at the first online meeting (left is Mr. Watanabe)

Online meeting with Taiwan factory

Hori: After meeting with Takachiho Trade, we had the Taiwan factory participate in the meeting as it was.

Watanabe: We were able to share a sense of schedule between the two companies, so we asked factory representatives to participate in order to have the Taiwan plant prepare materials and samples necessary for certification accordingly.

Hori: I'm sorry to say that it was a very good factory, and he immediately understood what I told me from here, and I remember that the response was very quick in everything. I personally feel that the real driver of this certification was actually the factory representative.

Watanabe: No. Basically, I think it's thanks to your company, but I also feel that the factory did well.

Meeting between Taiwanese factory representatives and engineers at the first online meeting (left is factory representative)

What impressed me the most since authentication started?

Watanabe: Since the certification started at an inspection organization in China, we have not had any particular details, and we have only been watching the interactions between the Taiwan factory and INSIGHT WORKS engineers.

Watanabe: However, engineers gave me instructions one after another for technical materials and samples to prepare, and the Taiwan factory responded steadily accordingly, so I had the impression that this would be something of a match.

Hori: The key point of certification is the response and technical capabilities of the factory, so I was relieved about that point. When I noticed the inspection of the production plant by the inspection organization, it was over lol.

Watanabe: That's right. The process progressed at a good tempo, and it is an impression that it was over before you know it.

Hori: The factory is located in Taiwan, but we were able to finish the remote test smoothly by a Chinese inspection organization.

Watanabe: Basically, I thought it was going well with PSE certification, but I was very impressed with the two re-examinations.

Watanabe: One is spacing (= internal wiring of the machine) and the other is outlet parts.

Hori: The former is a part that does not become a problem in other countries' tests, but the part to be inspected in the PSE test in Japan, the latter was ul certified parts, but in the PSE test, it will not pass unless it is a PSE or CE certified part.

Watanabe: When I heard that I had failed the exam when I was doing an examination at a Japanese inspection institution, I was nervous.

Watanabe: Because we produce at overseas factories, of course, we are making them based on overseas thinking, so we were able to inspect such places based on Japanese PSE standards. It was really helpful to receive consulting from the engineers.

Hori: As for spacing, the engineer came up with an idea for countermeasures, and the factory immediately made a sample, so I was able to pass the exam a little later than planned.

Hori: As for outlet parts, we found a supplier of PSE certified products by engineers and asked them to use them, so we passed the test.

Watanabe: Depending on the skill of the engineer, the product test, which I thought would happen for a moment, was completed a little later than the original scheduled date, and the rest was only waiting for the certification to be completed and the certificate was issued. I remember being relieved.

What's good about INSIGHT WORKS: Detailed communication, responsiveness, technical skills to manage troubles

Detailed contact

Watanabe: It really helped that you were able to contact us in detail each time the exam progressed. Basically, I have no choice but to leave the exams to you, but if there is any problem, I was contacted immediately, so I was able to focus on the production system and sales in Japan while grasping the overall schedule.

Hori: No matter which customer we have, we have been well received by our contact power, but since we do not inspect in Japan, it will be difficult for customers to see the overall flow, so we would like to follow that point firmly.

Hori: I remember that it was very easy to work because Mr. Watanabe responded to me every time immediately. Our goal is to be a partner in our work.

Responsiveness

Watanabe: This is similar, but I received a reply immediately to all the confirmations I asked for from here, and in the case of spacing issues, they set it up immediately at an online meeting with the Taiwan factory to consider measures.

Watanabe: Since it is necessary to adjust the time together for meetings, it may take about a week to hold if you are not good at it, but if you consult with us, you will respond immediately in 1 to 2 days, and I feel that there was no time loss in such a place.

Hori: There is a strong general image that "authentication takes time", but in fact, there is not much net time for authentication, and most of the communication and sample measures related to authentication are common.

Hori: For me, I think I know the point around there, so I have a stance of speeding up that part as much as possible and solving it.

Watanabe: Thanks to your response, I think we were able to devote as much time as possible to the work at the Taiwan plant.

Ability to respond to troubles

Watanabe: I don't say specifically one by one, but when the inspection agency told me that I failed each exam, I felt impatient every time lol, all of which I was able to clear thanks to the measures that engineers thought about.

Hori: I'm a veteran engineer I've been working with for many years, so I have a wide range of idea resources for countermeasures. Of course, it is best to pass each test in one shot without needing measures, but it is also difficult if you design the initial without 100% PSE knowledge.

Hori: So, in fact, it is quite efficient to put it out to the inspection at some stage without aiming for perfection from the beginning, and to take measures with all your might for the failure part. In addition, the overseas inspection organization designated by our company will tell you the pass or fail immediately in each test, so it is easy for us to demonstrate our power.

Hori: Japanese inspection organizations responded together instead of each exam, so we can't take measures each time, so I feel that there is not enough speed in that regard.

Watanabe: In that sense, I was very grateful for the advice of the engineers, and I feel that strange stories, if japanese inspection institutions had been testing as they were at the beginning, the certification would not have been completed on schedule.

Product body

Impressions after certification

Hori: After the exam was over, I feel sorry that it took a while for the inspection agency to have variously passed the certificate. However, we are relieved that we were all in time for the final product sale.

Watanabe: Certainly, I have the impression that it took a while since Mr. Hori contacted me about the end of the exam, and is it really okay at the last minute? I was honestly worried that, but I was contacted by Mr. Hori each time, so I left the rest and concentrated on what I could do.

Hori: Of course, there are many good aspects between Chinese people and Japanese (inspection institutions), but I also say that work is fundamentally slow.

Watanabe: Even so, I feel that INSIGHT WORKS approached inspection agencies in various ways to get work done quickly. In any case, in the end, we were on time for the deadline, so I am very grateful for the response.

Hori: I would be very grateful if you could say so.

Watanabe: This is the certification that has been completed safely, we were able to produce and sell as planned by our company, and we are very grateful that we are proceeding with our business smoothly.

Watanabe: As I mentioned earlier, if I had used a Japanese inspection agency this time, the certification would not have been completed on schedule, so I think that the decision I consulted and asked your company at that time was not wrong.

Hori: We learned a lot about the work of a listed company for the first time. Thank you very much this time. We wish you more success.