Can't you know everything in advance so that you pass at a time before PSE inspection at the Chinese factory? Answer as a "certification agency" to the question

この記事は約 26 分で読めます。 1,199 Views

Hello. It is a hori of the manager.

In the previous article "7 processes necessary when manufacturing and PSE inspection of large electrical appliances from ichi", I wrote about the flow of manufacturing from the first at the Chinese factory and performing the PSE test as it is.

As a sequel to this, we will clearly separate the position of our "agency" and "consulting company" in certification, and answer the question to "Can you grasp all necessary inspections before inspecting PSE specified electrical appliances at the Chinese factory?"

The story may be a little off, but first I will write about our stance.

We are calling itself "Certification Agent Service", not "Certification Consulting Company". Of course, we can provide authentication consulting, and we also provide consulting as part of certification agency for most cases.

To be honest, we still provide services beyond the scope of normal certification agency companies, but we have never named a "consulting company".

The reason is that, after all, it is the production plant that holds the approval or not. It is necessary for the factory to be motivated and proactively, and in addition to having a good understanding of Japanese certification and make product samples.

Of course, we will explain enough for that purpose, but ultimately, what is required is the independence of the factory. Therefore, if you name yourself a "consulting company", we are in the position of "agency company" in order to avoid being misunderstood if you let the factory do anything like a wizard.

It may sound like an escape, but if you make it a "consulting company", honestly, the current price is not enough at all.

In addition, if the factory does it independently, there is no need to consult, and since it only has to cooperate a little as an agency company, certification can be proceeded at a reasonable price as a requester.

Based on this premise, I would like to return to the previous question, especially in PSE Specified Electrical Appliances and Materials (Rhombus PSE).

Contents

- 1 It is the responsibility of the factory to prepare test samples, and the quality of the factory.

- 2 It is better to have the recognition that complex tests do not end all at once.

- 3 Cases where the test is not completed at once (1) EMC (electromagnetic compatibility) test

- 4 Cases where the test does not finish at once (2) PSE additional test of parts without all materials

- 5 Cases where the test does not finish at once (3) Special examination

- 6 Conclusion: If the factory takes the initiative, most tests can be completed.

It is the responsibility of the factory to prepare test samples, and the quality of the factory.

In the first place, from those who do not have authentication experience, "Can you pass the exam if you do?" I get a lot of questions.

To give you the answer first, it is not always possible to pass if you do it, and we will not refund unless we mislead, but basically we will not mislead. I have that confidence. In addition, there is no "failure" as long as the factory continues to produce samples.

One of the major reasons why we claim to be an "agency company" is that it is only the factory that makes samples, and we are in a position to give that advice.

If you become a consulting company, you will need to make samples quickly even if you put the neck of the factory, but it is impossible for a huge and wide variety of Chinese factories, and there is no such time and effort.

I would only encourage you to cooperate. And it depends on the cooperation of the factory whether the certification test can be carried out successfully, and in order for the factory to work with motivation, it is still important for the client to build a solid relationship with the factory.

So, "Can I pass the exam if I do it?" The question is that you are already trying to escape your company's responsibilities.

Of course, if you do not know the framework of certification, I will explain that briefly at first, but if you think that it is unconvincing that it is your job to pay more cooperation to the factory, sorry, but the act of authentication should be stopped at this point.

In addition, we fully explain what kind of samples are required for each certification such as PSE, PSC, radio law, etc. to the factory, but it is the factory that actually creates it by moving your hand.

To be clear, we basically know what kind of things to make, and the point is whether the factory can reproduce it.

The quality of the sample itself cannot be secured by our company, and in that sense, we are a "agency company".

Some companies have said that it is our responsibility to reexion the test when the factory takes the lead in production and certification, but basically the quality of the product is the responsibility of the factory, and if I say strongly, it is the responsibility of the client.

We provide necessary advice from the standpoint of a certification agency, but since it is not a consulting company, it is not compellent to make remarks, and it is the work of the factory to realize it by ourselves.

If you need advice on a quality that ends at once, it will be consulting, and our current costs will not be in time, and the actual situation is that it will eventually cost more than retesting.

I hope you will remember that the development of machines is so much money.

It is better to have the recognition that complex tests do not end all at once.

I don't know if it's unique to Japanese people or overseas, but basically, additional costs are disliked in business.

Naturally, I think so, too. It is a normal feeling that you basically do not want to pay additional expenses no matter what you do.

However, I think that it is not a good thing at all, but it is a difficult story in the world of authentication (the world of mechanical design).

In particular, in PSE electrical appliances and supplies, a single machine is subjected to a truly various parts and parts, and tests are performed on each of them. It is stipulated in Japanese law as such.

Of course, the producers do their best to produce everything in accordance with PSE, but it is precisely the area of god work, and that is the more clever way of testing to discover the bad while doing PSE tests and take measures one by one.

Of course, in pse specific electrical appliance and material testing, we check the product parts list in advance, check the necessary materials and parts, and explain what kind of test will be performed at the factory.

However, that said, I try to take the exam once first except that I am not using a JET outlet in Japan, which is obviously useless.

So while listening to the feedback of the inspection agency, the factory is given instructions on countermeasures, and the test is completed by the accumulation of such things, which is done with a new sample.

Basically, you'd better think that a single exam won't make everything perfect.

If you take the stance of not conducting the test until you clear everything in advance, the confirmation will not end forever, and the authentication will not progress until how long.

Again, basically, it is a common idea in business that we do not want to pay as much additional expenses as possible, and of course we think so, but it is very difficult in the current world of authentication, but it is true.

If you really don't like it, I can only advise you that it's wise not to deal with products that require certification from the start.

On the other hand, the reason why we certify in the first place is to deliver safe and secure products (electrical appliances) to consumers, and the fact that the test cannot be passed is dangerous to consumers. By all means, I think that you should not forget that point.

Cases where the test is not completed at once (1) EMC (electromagnetic compatibility) test

Emc and others are not very familiar with living normally, but it is actually a very important story in the world of electronics and is a fairly important item in pse testing.

The following is an overview from the specialized site.

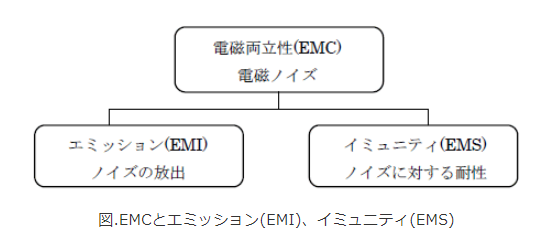

EMC is an acronym for Electromagnetic Compatibility, which is defined as electromagnetic compatibility in JIS.

That is, the device must be designed and manufactured so as not to become an electromagnetic interference source, and to operate normally even if it is received (compatible) so as not to receive electromagnetic interference.

As shown in the figure, electromagnetic compatibility is divided into emission (EMI) and immunity (EMS). Emissions (EMI) are phenomena in which electromagnetic energy is emitted from a source.

On the other hand, the ability of equipment to operate without performance degradation or malfunction in response to performance degradation and malfunction that can occur in surrounding devices due to emissions (EMI) etc. from equipment is called immunity (EMS).

EMC is used in the sense of environmental electromagnetic engineering and electromagnetic environment, which means academic field. On the other hand, as a technical term, it is used in the sense of whether there is consistency or compatibility with electromagnetic problems of electrical and electronic equipment.

Specifically, when the electromagnetic interference emitted from the device is small, operates normally against some electromagnetic interference from the outside, and does not malfunction with the device itself, the device has EMC. It is called electromagnetic compatibility.

Citation: CEND.jp -Emc Countermeasure and Noise Suppression Comprehensive Information Site-_1. EMC Overview

Simply put, almost all electrical appliances emit electromagnetic waves, and design and manufacturing must be devised so that they do not interfere (adversely affect) humans and peripheral devices.

There are various standards in various countries around the world, and there are standards established by JIS in Japan, and they are adopted in the PSE test. It may be a good thing from a Japanese manufacturer, but from an overseas manufacturer's perspective, it is necessary to match the EMC standards in Japan, but it is difficult to match it at once from the beginning.

Therefore, it is quite efficient to take measures after first trying the test and confirming the opinion of the inspection institution. Of course, you may pass from the beginning, but you may want to think that it is unlikely.

Please remember the existence of this electromagnetic compatibility test.

Cases where the test does not finish at once (2) PSE additional test of parts without all materials

As we proceed with PSE testing, for example, when a socket (an appliance that attaches a light bulb, bean bulb, LED bulb, etc.) is used inside the product, the socket itself may need to be PSE certified or CE certified.

In short, it is not permitted to use the part which does not know the true body as it is. Regardless of whether this system is right or wrong, certification is required not only for the product itself but also for the parts used for it in order to ensure the safety of the product.

Of course, because the engineer of a proper factory knows such a thing, I use certified parts as much as possible, but especially when it comes to overseas factories, I am not aware of Pse in Japan, so I often use parts that are not recognized by Japanese certification.

You also need to get a certificate from a supplier (parts manufacturer) to see if the part is truly certified.

In addition, if the part itself is not certified or the part certification certificate is not aligned, parts tests must be carried out to apply only to the product to be tested this time.

Once, a Japanese parts manufacturer did not provide a certificate by all means, and it seems that it is not possible to make it until the scheduled date of the test, and I switched the supply destination of the used parts overseas in a hurry, installed overseas parts, received the certificate in a hurry, and had the experience of making the test in time.

Some people feel that we are rip-up and feel that there are additional parts tests, but to be honest, most parts testing is actual cost and it is only laborious. To be clear, it is more helpful for us not to do part testing, but in a sense we are doing it in a sense to advance PSE certification.

If you are doing PSE certification, please be aware that there is a thing called "parts test".

Cases where the test does not finish at once (3) Special examination

For example, on machines equipped with compressors (air compressors), compressors alone may be tested.

Even if it is said that it is a compressor in a word, there are various applications such as using air pressure to move the built-in product, adjust the volume, and cut things. Even if there is no problem with the compressor itself, the usage may change depending on the application, and it may be necessary to test the compressor contents according to the product.

In our previous case, the compressor erupted during the test, and of course the compressor test failed.

As a countermeasure, we introduce suppliers that we know and change the compressor itself. In addition, we reworked the installation method with the product, tested it again, and passed the test safely.

I think that introducing suppliers in this way is basically not the job of an agency company, but we may propose as necessary measures to facilitate the examination.

In any case, there is no way to know whether there is a problem with the parts that the factory is already using, and if you want to grasp all of them in advance, it is the same as doing PSE tests twice, so the cost and the period will double.

Conclusion: If the factory takes the initiative, most tests can be completed.

I have written a lot of things in various ways, but in conclusion, at least we have the necessary know-how to pass the inspection as a certification agency, so it is important whether the factory will proactively execute this instruction.

In addition, a good relationship between the client and the factory is essential for this. I think that you can remember it by all means because the speed of authentication is decided whether it is or not.

And finally, when I answered the question "Can you grasp everything so that you pass the PSP specified electrical appliance and material inspection at the Chinese factory at the Factory in China?"

I have told you many times on this page,

It is difficult to grasp, and if you want to do it, you will charge the cost as a consulting company instead of the cost of the certification agency, and after all, it will be higher than the additional exam. Rather, it will be cheaper as a result to determine in some places and proceed with some resolution for additional exams, and above all, you can finish the test quickly,

It is an answer.

In order to achieve this, we believe that the factory needs to cooperate independently.

I feel sorry that there is only our company as a certification agency that has been explained so far. If there is a company that is calling himself a certification agency and consulting company elsewhere, please ask about this, and I think that you will understand the most ability.

We accept consultations at any time to complete the certification safely, so please feel free to contact us if you have any orders.