7 processes necessary when it comes to manufacturing large electrical appliances and materials (vending machines, electric sauna baths, etc.) and PSE inspection from scratch

Hello. It is the moat of the caretaker.

Recently, I would like to write about the flow of manufacturing and PSE inspection at the Chinese factory for large electrical appliances and materials, where inquiries are increasing.

Until now, this site has mainly written about obtaining certifications such as PSE and Radio Law, which are basically necessary for OEM sales of ready-made electrical products of Chinese factories.

This time, for customers who want to work from the manufacturing itself, I would like to introduce how to proceed with the project based on our case studies and so on.

I'll start with something a little negative.

When manufacturing from scratch, it starts from ordering molds, so the cost will be quite large, and if you do not order several thousand pieces at the time of this order, the factory will not get along.

In addition, in the case of electrical appliances, PSE inspection is required after sample production. In other words, on the premise that it will be distributed in the Japan market, we must procure and install design and parts.

Words are bad, but they don't mean that they should be made, but they need to be designed according to certain criteria.

If it is a product of about the size that can be handled by hand, it may still be possible to manufacture it somehow, but if it becomes a large product, the number of parts to be used will increase, so we will make it quite carefully while keeping in mind the parts and equipment necessary for PSE certification.

If you are a factory that has performed PSE inspection many times, it may be possible to manufacture just by consignment, but there are basically not many such factories, and even if you are strong in PSE, it is meaningless if you can not make the product you want to make.

Fundamentally, the first step is to find a factory where you can make the product you want to make. Since we are going to instruct PSE at that factory, naturally the difficulty level will be quite high. To be honest, I think it will be a project that cannot be done at the level of trying to do it for a while.

However, that is precisely why it is a business opportunity that other companies can not easily enter.

Also, as a place to begin with,

Is it possible to make such arrangements?

Isn't this a story that only major companies can do?

Some of you may be wondering.

We can help you with the technical aspects. If you take a look at this article, you will get a rough idea of the process.

On the other hand, on the financial side, of course a certain amount of funds are necessary, so most of the companies may be medium-sized or larger, but even if you are a small business, there is nothing that you can not do if you use funds well.

I think the point is whether there is such a business story or not.

Looking at this article, I think that if you can learn that there is such a business and that it is not impossible at all, it will be a reference when thinking about new business in the future.

Contents

- 1 Rough flow

- 2 Product specification determination (factory selection)

- 3 Certification guidance to factories

- 4 Parts procurement

- 5 Sample creation (for company confirmation)

- 6 Sample creation (for inspection)

- 7 Guidance before inspection to the factory (in the case of specified electrical appliances)

- 8 PSE inspection

- 9 Specific examples~Vending machines~

- 10 Specific examples~Electric sauna bath~

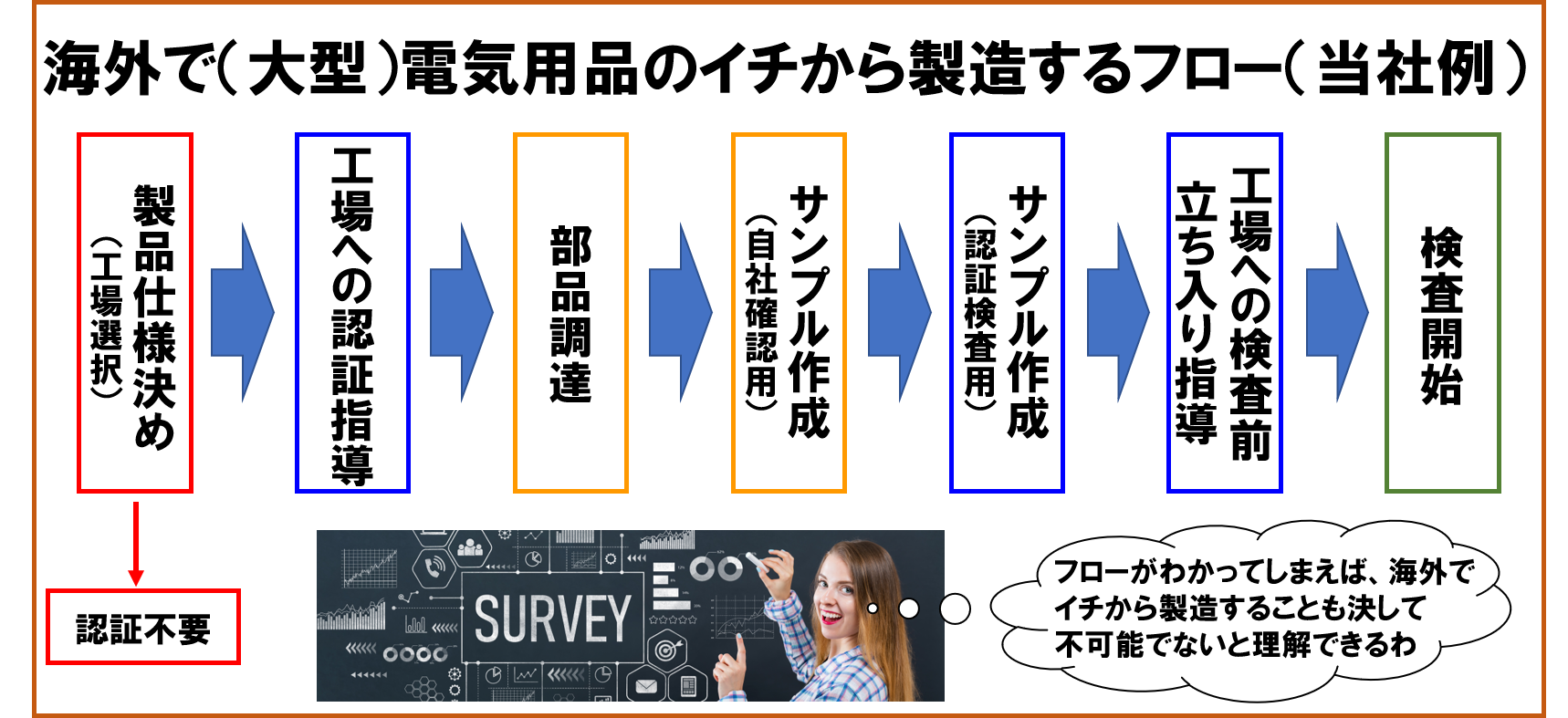

Rough flow

I will write individual explanations sequentially from now on, but the general flow is such an image.

This is also a comment in the figure, but if you can understand this flow, you will get an image of how to actually proceed and you will understand that it is not impossible to manufacture large-scale electrical appliances overseas from scratch.

Let's keep this knowledge in mind first.

Let's explain each process.

Product specification determination (factory selection)

If we do not decide on this point, we will not be able to move.

However, our strength is that we can always certify whatever specifications are used.

For example, I think that it is necessary to decide various specifications for each product, such as switching function, thermal function such as thermo heater, and cooling function opposite, but do not worry about the certification that will be held later.

In addition, if you want support from the factory selection, it will be a separate cost from certification, but we also support it.

In addition, it is also possible to arrange a preliminary visit to the factory, but whether it will actually be realized or not depends on the convenience of the factory.

Certification guidance to factories

Once you have decided on the general specifications of the product, the first thing you need is certification guidance (PSE consulting) to the Chinese factory.

This must be done to the factory site to actually check the equipment of the factory and to install cooperation.

Furthermore, what we need to do most is to make the Chinese factory understand the Japan PSE method to some extent.

As I have told you many times on this site, it is very difficult to understand (to some extent) the laws of Japan in a foreign land called China.

Even in Japan, it is difficult to manufacture products while understanding the laws of other countries, so it is necessary to have a consultant who is familiar with the laws of the country in question, or to produce products by setting up a factory locally.

If electrical appliances used in Japan are to be produced at a factory in China, they must understand the laws of Japan.

First of all, Japan PSE has a system, what kind of safety standards it has, what kind of parts are necessary, and the product samples made are certified by inspection organizations, and if you do not tell the president or site manager class, you will not proceed.

Even if you make a mistake, it is not a story that can be moved by the person in charge alone.

People who have never seen a production site sometimes seem to be under the mistaken impression that a factory can do anything once only instructions are given, but of course this is not the case.

Since what is made is a machine, of course it is not enough to assemble it appropriately, but it must be done precisely, and the main source of this is that the factory must start with the awareness that it makes products that conform to the Japan PSE standard.

We also provide consulting at such factories, so please feel free to contact us if you have any orders.

Parts procurement

At the factory site, we conduct consulting and at the same time check the production equipment of the factory.

Compare them to the product specifications you want to make and create a list of parts that are required for PSE inspection and generally required to achieve that specification. (Format is on a case-by-case basis)

The customer and the factory share this information, decide which part to arrange, and proceed with procurement.

Based on the procured parts, the factory will create a list of parts to be used in PSE inspections. The point here is that as long as they perform their function, it is not as if any part is good, but where necessary, parts that comply with the Japan PSE safety standards must be used.

Of course, the factory does not know about this, so it will be difficult to realize it unless we welcome consultants like us.

Major companies spend tens of millions of yen on such development, but one of our strengths is that we can do it at an order of magnitude cheaper.

Through such consultations, the factory creates blueprints such as product schematics and specifications.

Sample creation (for company confirmation)

Don't be impatient, you need to first check the sample to see if the product you make from scratch is satisfactory for your company. The final form is never completed suddenly.

Please carefully check to see to what extent the specifications you envisioned have been realized beyond the walls of factory production technology and PSE.

Even while the factory is producing, your company's representative should be packing, and our company also answers questions from the factory sequentially and reports to customers as necessary, so at the time of completion of the first sample, there is basically no chance that a machine that you have never seen before will be finished suddenly.

However, it is the first time that you will see something that is still shaped as a machine, so please consider various things there.

In addition, if necessary, if there are products and parts other than PSE that are required, it is necessary to prepare suppliers to procure them.

Sample creation (for inspection)

After checking the sample for confirmation throughout, if it is acceptable, we will inform the factory of the correction point, and then we will make a sample for PSE inspection.

When it comes to inspection, it is necessary to make it almost as well as what is distributed in Japan, so communication with the factory becomes closer.

Whether it is really okay to proceed as it is with the specifications of the request, what is the situation of parts procurement, etc.

If parts were not available by all means, factories would continue to contact us almost every day to see if it was possible to use a replacement.

Naturally, we will also support you.

Guidance before inspection to the factory (in the case of specified electrical appliances)

In particular, in the case of specified electrical appliances and equipment, there is a visit inspection to the factory by the inspection organization, so the factory must prepare production equipment and respond to inspection organization staff.

In the past, chinese inspectors and chinese factory people talked to us, so will you do well around that? I had a question, but don't say anything stupid.

There may be such low-level inspection agencies, but basically they work seriously, and the Chinese inspection organization for specified electrical appliances is strictly handled by international inspection organizations such as TUV and CQC. So I think it's better not to look too sweet.

Under consulting guidance, there will be no problem with on-site inspections because it is a factory with enough production function to make PSE products, but considering the effort so far, I think it is important to create a system for PSE testing again.

Provision of factory production facilities that cannot be underestimated

Of course, if you don't have experience, you won't know, but in fact, the preparation of this production facility is quite a songwriter.

To give a brief overview, under the provisions of PSE specified electrical appliances, factories are obliged to ensure that PSE products are produced in accordance with PSE technical standards. At that time, you must have an oscilloscope, pressure resistor, etc. necessary and become able to use these machines well. On-site inspections of factories by inspection agencies come to confirm this.

These facilities are defined by the standards of the PSE (Electrical Appliance and Material Safety Act). In other words, it needs to be a Japan machine or a machine that covers Japan standards, and it can be difficult or very expensive to find in China.

Factories that are accustomed to PSE will have such facilities, but factories that are doing PSE (Specified Electrical Appliances) for the first time will almost certainly not have them.

How much does PSE cost?

It is often asked, but in addition to PSE testing, there are actually such hidden costs. If you do it poorly, there is a possibility that it will be equivalent to the PSE test. We will also support you to keep these actual expenses as low as possible, but first of all, I would like you to keep in mind that there are also such expenses.

PSE inspection

Once the inspection actually starts, there is no special need for the customer to do it.

PSE inspection requires documents such as circuit diagrams, specifications, and component lists along with product samples, but there will be no problem if you leave that to the factory.

Once the inspection starts, there will be a rough estimate of the timing of the completion of the inspection, so leave the inspection itself to the factory and a consulting company such as our company, and for the customer, please do more and more things that are piling up, such as developing a channel for distributing the product Japan and creating product packaging.

If it is about online sales, we can give advice, but when it comes to large-scale products, there will be a company's own sales network, so I don't think we can support that.

We ask our customers to concentrate on that, and we will do our best to ensure that certification proceeds perfectly.

In addition, we will support you so that you can smoothly complete the application procedure to the Ministry of Economy, Trade and Industry.

I wrote about the series of processes for manufacturing large-scale electrical appliances in China. If you look at it this way, you'll see that it's not impossible.

There may not be many opportunities to find business opportunities in the manufacture of large-scale products, but if you still know that it is possible, you will have an advantage when you encounter such opportunities in the future.

We hope this article will help you develop your business.

Specific examples~Vending machines~

So, what kind of products are large-scale products?

From our example, it is a vending machine (vending machine).

You may wonder if vending machines needed PSE certification in the first place, but in fact they are necessary.

To put it in a little more detail,

Large vending machines that sell juice, alcohol, food, etc. both outdoors and indoors are specified electrical appliances and materials (rhombic PSE).

Small items that mainly sell tickets indoors will be ticket vending machines other than specified electrical appliances and materials (round PSE).

In the case of specific electrical appliances and materials, it is basically as described above.

Why do you want to do a vending machine business?

Until now, vending machines have been a monopoly market for major beverage manufacturers and liquor manufacturers. The vending machine itself is also an oligopoly of major specialized manufacturers.

However, recently, the number of Chinese Vender (vendor) manufacturers such as for Europe is increasing. The performance is also quite good, and the number of business operators who want to import it and sell original products of their own company and business partners is increasing. The cost of PSE testing is not cheap by any means, but it can be said that it is cheaper than developing from scratch.

Honestly, only our company can certify Chinese vending machines with PSE certification!?

If it is produced in Japan, it is common to use a domestic inspection agency JET, but if it is made in China, you must first import the sample into the Japan. It is quite difficult to transport only one car, and with JET there is a possibility that it will be quite expensive due to problems with 50hz / 60hz.

If you are interested, I would like to ask you once.

Click here for an article about vending machines.

Specific examples~Electric sauna bath~

Recently, I think that many people know that sauna is booming due to the influence of celebrities and influencers.

As the boom becomes popular and takes root as a new culture, there will inevitably be people who will try to do business in such areas.

Currently, the production of the following private room type saunas is progressing in China, and the number of businesses that are trying to introduce them is increasing.

In addition to being easy to enter in a private room, heat is injected into the body using far infrared rays, so the room itself is excellent that you can enjoy the sauna without being so hot. These electric sauna baths are produced in China.

In addition, the number of sauna heaters used in saunas is increasing. In fact, these are subject to PSE.

Honestly, only our company can certify electric sauna baths etc. made in China with PSE certification!?

It will be the same as a vending machine, but if it is domestic production, it will be common to use domestic inspection agency JET, but if it is made in China, you must first import the sample to the Japan. It is quite difficult to transport only one car, and with JET there is a possibility that it will be quite expensive due to problems with 50hz / 60hz.

If you are interested, I would like to ask you once.