What are the risks and disadvantages of authentication such as PSE, PSC, and radio law for those who feel the risk of authentication?

Hello. It is a hori of the manager.

In the previous article, I told you the merits of authentication.

It is also true that if there is a merit, there will always be a disadvantage or risk.

If you do not tell them properly, you will not be able to correct information.

I hope that you will read the negative information about authentication together with the merits and deepen your understanding of authentication.

However, there are few unique disadvantages of PSE, PSC, and radio law certification, and if you import products of any genre to China (overseas business), it will always occur.

I would like to tell you what we felt in our unique experience and customer's experience of certification, and what is prone to risk at the time of authentication.

Contents

- 1 You'll be charged a big take-out cost first

- 2 I need the factory to submit the documents.

- 3 There is a possibility that the factory will be deferned during the busy season.

- 4 Parts suppliers don't cooperate with the factory, even if they want to cooperate.

- 5 Inspection agencies may not understand the inspections

- 6 Factory cannot be changed after certification/ There may be many defective products

- 7 However, in the end, these are all problems that arise if you import China.

You'll be charged a big take-out cost first

This alone will be a story of authentication, but it is still an item that is not another general product to pay the cost in advance for authentication.

Also, the authentication cost is basically prepayment.

We have such a fee structure, which is the same wherever you ask.

The inspection organization will arrange personnel and equipment on the premise that the requested certification will be carried out without delay, so it is necessary to collect the cost in advance.

Of course, if there is too much in the event of a boycott on the way, it may be refunded, but in any case, it is customary that the inspection institution will not move unless you pay the cost first.

In that sense, it is also true that it is difficult to tackle without a determination that "this authentication absolutely needs to be done to the end".

You may need factors and motivation to authenticate, such as knowing that it will sell to some extent, and necessary as a business infrastructure.

It is also true that such a point raises the threshold of authentication.

However, this is a difficult problem, and if he can easily authenticate (entry) too much, for example, poor products by low-level suppliers will be brought to inspection institutions, and there is a concern that inspection institutions will also puncture.

If you do so, there is a possibility that the inspection that can be done normally will be defernated.

It is not easy to discuss whether a high threshold for authentication is good or bad.

On the other hand, I have said many times that it is also true that taking measures to overcome such high barriers and passing the examination is the first step toward higher levels as a business operator.

I need the factory to submit the documents.

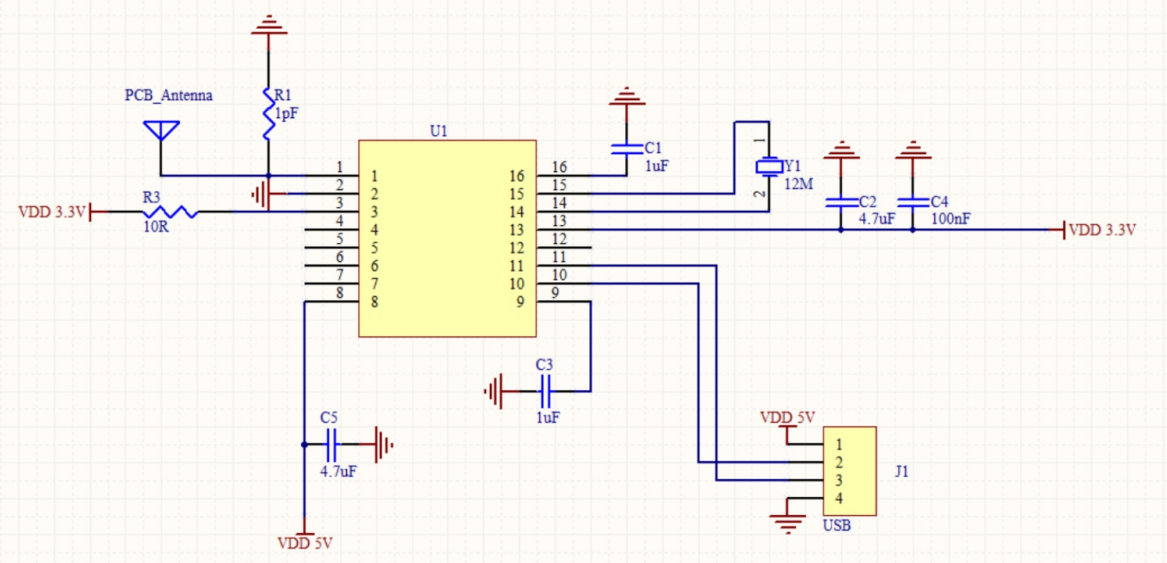

Take a look at the image below as an example.

This is a schematic of the laser pointer that we have certified.

In order to perform the certification, it is necessary to submit documents (technical documents) related to such products to the inspection body.

When we performed our first certification, we did not have the know-how and knowledge as we do now, so when we were asked by an inspection agency to submit technical materials, we realized that we could not compete with the management system so far, and gradually established a system that can certify.

In the first place, it is difficult to express "technical materials" in the local language to factories in China (overseas).

There is a factory where assembly is done only in the inside, and technical materials often do not come out straight though it only has to be where the factory which deals is producing neatly.

That's why some businesses give up without being able to check the materials at the factory.

Under such a number of years, we have the know-how to check materials in the factory and local language, so I would like to consult with you.

There is a possibility that the factory will be deferned during the busy season.

China, which is said to be the factory of the world, is busier than we think japanese people.

In fact, certification itself is a work that does not generate even 1 yen for the factory.

In addition, there are many things to do, such as documents and samples that need to be prepared, so it is difficult to get a dispute that it is inadvertently put off.

One solution is to aim for the quiet season of the factory, and there are ways to negotiate, such as promising to purchase a certain amount from the beginning and actually paying the purchase cost of the product first.

In November, we began to have time at the factory, and we were able to proceed at once and were involved in passing the inspection.

In addition, there are many cases where the person in charge does not understand the business contents due to lack of experience.

Then, because it becomes helpless, the person in charge and the factory change, etc. might be necessary in some cases.

Based on our experience so far, we can also do connoisseurs at the level of the person in charge, and we can also find and know factories that perform other certifications.

Parts suppliers don't cooperate with the factory, even if they want to cooperate.

On the other hand, it is also true that we would like to cooperate in certification as much as possible because it is a prospect that the factory will purchase our products regularly.

If you live normally in Japan, you may not have much image, but many parts occur to make a single product.

The factory has various suppliers provide parts for product production.

In addition, there is a case where the certification is performed is not so much as a whole product, but a case where each part is inspected while checking the entire circuit diagram.

In other words, the factory wants to cooperate in certification, but there are cases where it does not proceed unless the supplier submits a sample (such as parts) and documents related to it.

This will take a little time. There is also a solution to this, but please remember that there are various factors that the factory is slow to respond to.

It is not necessarily only the sabotage of the factory.

If you do not understand this area, you will simply catch the problem because the factory is slow, and you will not be frustrated and your qualities as a business operator will not go up, such as "After all China cannot be used".

Inspection agencies may not understand the inspections

I had received consultations from customers before, but the factory I contacted had already obtained PSE and paid the product price first, but I wanted you to see the PSE certificate that came out because it was suspicious.

When I looked at it, it was certainly strange content.

The voltage described on the certificate is 200 V (*The basic voltage in Japan is 100 V), the electromagnetic school is only 50Hz (*50Hz is eastern Japan, and western Japan of 60 Hz is usually also required), and there is no sign of the certification person in charge.

The inspection certificate comes with a report describing the inspection contents that you have done, but when you tell the factory to submit the report, there is no answer at all.

We have determined that this certificate was fake (counterfeit) or entrusted to an inspection organization that the factory is not familiar with and is not familiar with.

I instructed the customer to get a refund to the factory.

And I have experience of introducing other factories that I do properly.

There are many inspection organizations located in China, and of course we have secured inspection institutions that are familiar with Japanese inspections, but some inspection organizations that perform inspections suitable for job desires should be careful.

There is also a risk that if you issue a certificate to the Ministry of Economy, Trade and Industry after paying a large sum of money, it will not be accepted.

As a reason for this, China is a factory in the world, so there are inspection organizations around the world, such as Europe and the United States.

Of course, there will be inspection bodies that are not familiar with Japanese certification.

Be careful about that area.

Factory cannot be changed after certification/ There may be many defective products

Even after successful certification, even if the inside of the product is safe, the quality of the product may be low.

When we were dealing with wireless presenters, as a result of inspections, sometimes the irradiation angle was slightly bent about 3 degrees.

When I contacted the Chinese factory, I insisted, "It's not as bad as this!"

No, no, it's a defective product.

However, this factory is the only plant that has passed the PSC inspection, and it is not practical to replace it with another factory.

Once again, when we conveyed that we would like to work together to improve our product capabilities in good faith, our attitude has softened.

It is difficult to change the factory after certification, but since it is at the factory level that responds to certification in the first place, there are many cases where people think positively about measures against defective products.

This requires business consultation.

Guangzhou exhibition in China.

There is no direct relationship with this article.

However, in the end, these are all problems that arise if you import China.

If you write so far, you may think that it is better not to authenticate.

However, in the end, as a view of our experience dealing with both certified products and other products, I feel that it is a common story in Chinese factories except that we need money first.

China import is a back-to-back with such troubles, and in the end, the problems must be cleared one by one, and there is nothing but to leave it to the passion of the business operator.

Of course, we will also support you.